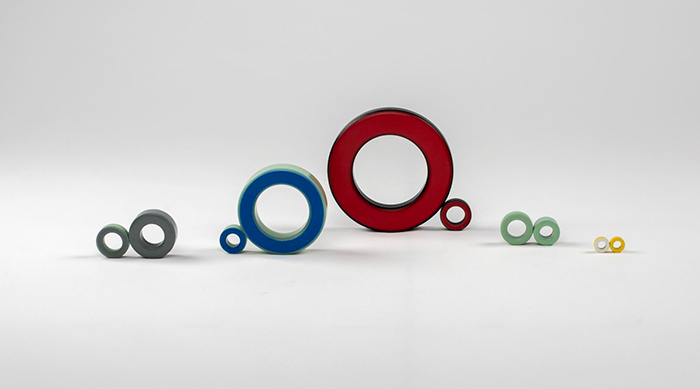

Iron powder core is a soft ferromagnetic material based on pure iron or carbonyl iron powder; mixed with binding material and pressed to form.The surface is coated with insulation material. Iron powder core has a high magnetic flux density (14000Gs), so it will not saturated under high magnetic field. It has a very good DC superimposed characteristic.